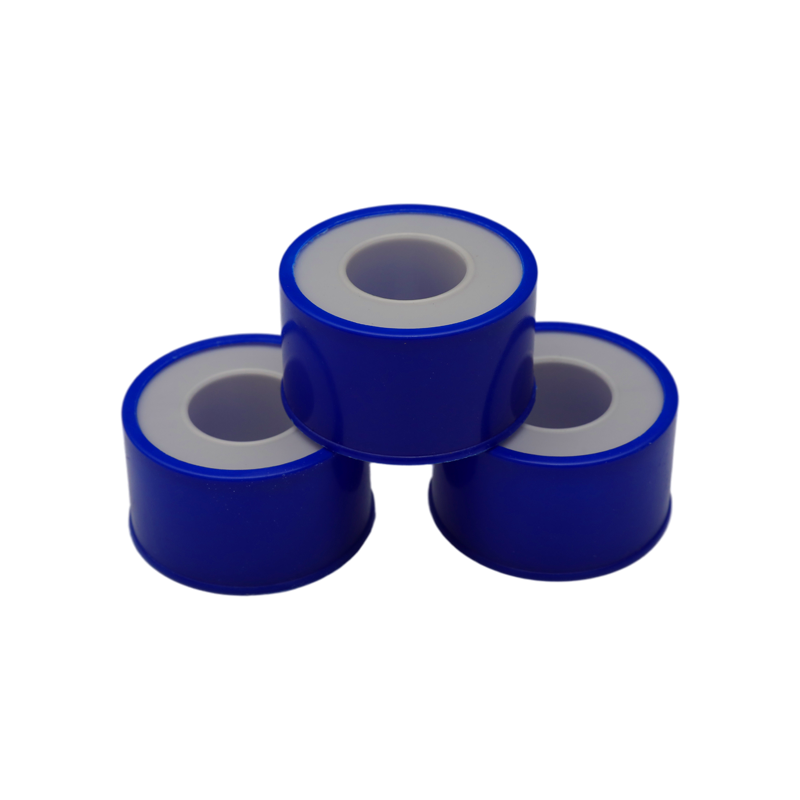

25MM Teflon Tape, made from polytetrafluoroethylene (PTFE), offers several advantages over other sealing materials, particularly in terms of temperature resistance and stability. These benefits make it a preferred choice in various demanding industrial applications, such as high-temperature environments and chemical processing. Below are the key advantages:

Teflon tape stands out for its exceptional temperature resistance, making it suitable for extreme conditions where other sealing materials may fail.

PTFE can withstand temperatures ranging from -200°C to +260°C (depending on the formulation), which is significantly higher than many other sealing materials like rubber, silicone, or even some metals. This makes Teflon tape ideal for applications involving steam, hot liquids, or high-temperature gases.

PTFE retains its flexibility and sealing properties even at very low temperatures, unlike elastomers (such as rubber or silicone) which can become brittle and lose their sealing effectiveness at low temperatures.

Teflon exhibits excellent thermal stability during rapid temperature fluctuations or cycling, which means it can maintain its integrity in environments that experience wide temperature variations. Unlike other materials that may degrade or crack due to thermal stress, Teflon tape remains stable, ensuring long-lasting performance.Many sealing materials, including some types of rubber or plastic, degrade over time when exposed to high temperatures, losing their sealing capabilities. Teflon, however, is highly resistant to thermal degradation and maintains its sealing properties over prolonged exposure to heat.

PTFE is chemically inert, meaning it does not react with a wide range of chemicals even when exposed to high temperatures. This gives Teflon tape an edge over materials like rubber or cork, which may break down or lose their sealing ability in the presence of chemicals or high heat. In applications like petrochemical plants, pharmaceutical industries, or food processing, where aggressive chemicals and high temperatures are common, Teflon tape provides reliable sealing.

Teflon tape has a very low coefficient of friction, which means it can handle dynamic movements and thermal expansion better than many other sealing materials. This low friction property ensures that even with temperature fluctuations, the tape does not suffer from friction-related wear and tear, making it a durable option for high-temperature sealing.

Because of its high-temperature resistance and stability, 25MM Teflon Tape has a much longer service life compared to many conventional sealing materials. This is particularly important in environments where seals need to last for extended periods without failure. Materials like silicone and rubber may need frequent replacement due to heat-induced degradation, whereas Teflon maintains its effectiveness over time, reducing maintenance costs and downtime.

Teflon tape is versatile enough to be used in a wide range of temperature-sensitive applications. From cryogenic processes to high-temperature gas systems, Teflon tape can handle diverse conditions without compromising on sealing performance. Other materials, such as rubber or cork, have limited applications due to their lower temperature tolerance.

Many sealing materials, such as rubber, are prone to creep or compression set under constant pressure and temperature stress. This can result in loss of sealing integrity over time. Teflon tape, however, resists creep and maintains its form and sealing capacity even under prolonged exposure to high pressures and temperatures. This feature makes it ideal for use in high-temperature pressure systems where reliable sealing is essential.

In comparison to other sealing materials, 25MM Teflon Tape offers superior temperature resistance, excellent thermal stability, and long-lasting performance in extreme conditions. Its ability to withstand both high and low temperatures, coupled with its chemical inertness and low friction properties, makes it an indispensable material in industries where sealing at high temperatures is critical. Other materials, such as rubber, silicone, or metals, cannot offer the same level of durability and reliability when subjected to harsh temperature conditions, which is why Teflon tape is often the preferred choice for sealing in demanding environments.

English

English Espa?ol

Espa?ol