To ensure that 19MM PTFE Thread Tape can effectively prevent leakage after winding, you need to pay attention to the following key steps and tips:

Before using PTFE Tape, make sure there is no oil, dust or other impurities on the thread surface of the pipe. You can clean the surface with a cloth or brush, and use solvents (such as alcohol) if necessary.

Avoid corrosive substances: Make sure there is no corrosion or rust on the surface of the pipe, otherwise it will affect the sealing effect of PTFE Tape.

Choose a suitable PTFE Tape according to the material of the pipe (such as metal, plastic, etc.) and the medium it carries (such as water, gas, oil, etc.). Make sure that the selected Tape has sufficient chemical resistance and temperature resistance.

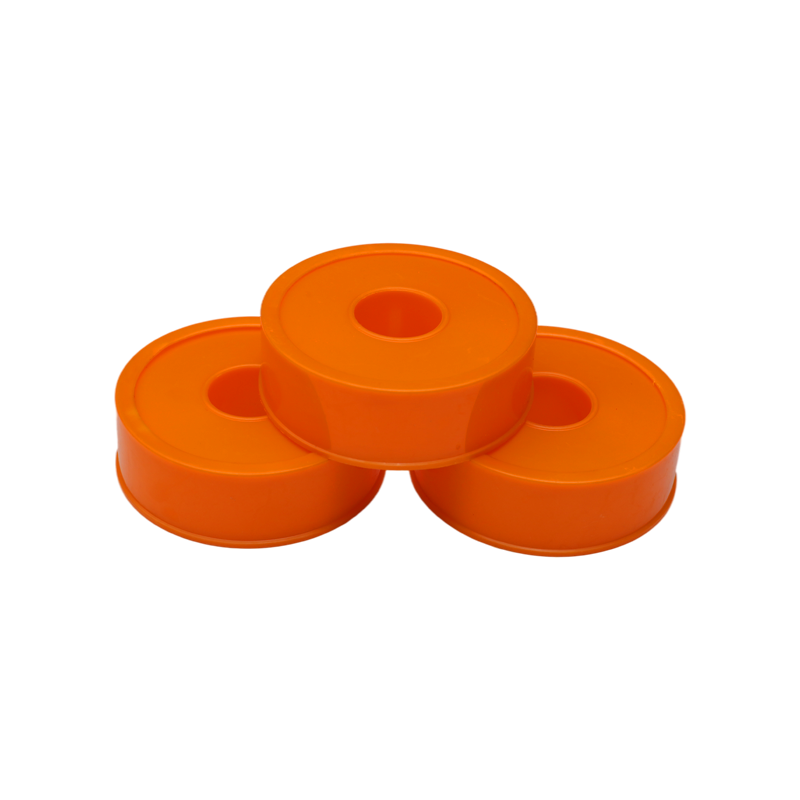

19MM wide PTFE Tape is usually suitable for larger threaded connections. Make sure that the thickness of the Tape is sufficient to meet the needs of pipe sealing.

When winding, the PTFE Tape should be wound according to the direction of rotation of the thread. If the pipe thread is right-handed (usually standard thread), the Tape should be wound counterclockwise; if it is a left-handed thread, it should be wound clockwise. This ensures that the PTFE Tape will not be pulled apart or displaced when connected.

Depending on the size of the pipe thread, 3 to 6 turns are usually required. For larger diameter threads, more turns may be required. Make sure that each turn of the tape covers the thread evenly, but not too much to avoid affecting the tightness of the connection.

When winding, make sure that the PTFE Tape is evenly distributed on the thread surface, leaving no gaps to avoid leaks due to local weakness.

When threading, do not overtighten. Overtightening may cause damage to the pipe or joint, and too loose will not form an effective seal. Use appropriate torque to connect according to the thread standard to ensure that the sealing tape can fully function.

After installation, the pipe connection can be pressure tested or visually inspected for leaks. If there is a leak, check whether the PTFE Tape is evenly covered or whether it is improperly wound.

If a slight leak is found, the PTFE Tape can be disassembled and rewound, or a layer of Tape can be added to enhance the seal.

After long-term use, PTFE Tape may age due to temperature and pressure changes or mechanical damage. Check the sealing status of the threaded connection regularly and replace the new PTFE Tape if necessary to avoid leakage.

If the PTFE Tape is subjected to excessive pressure for a long time, it may deform or lose its elasticity, affecting the sealing effect. Therefore, try to avoid excessive pipe pressure or thermal expansion from affecting the PTFE Tape.

In some special cases, if additional sealing is required, you can consider adding a layer of sealant or glue to the PTFE Tape to further enhance the sealing effect. This is usually used in occasions where strict sealing is particularly required.

Make sure that you use reliable quality PTFE Tape. Poor quality PTFE Tape may contain impurities or uneven thickness, resulting in poor sealing effect.

Through the above steps, ensure that the 19MM PTFE Thread Tape can be wound evenly, fully cover the pipe threads and be installed correctly, thereby effectively preventing leakage.

English

English Espa?ol

Espa?ol