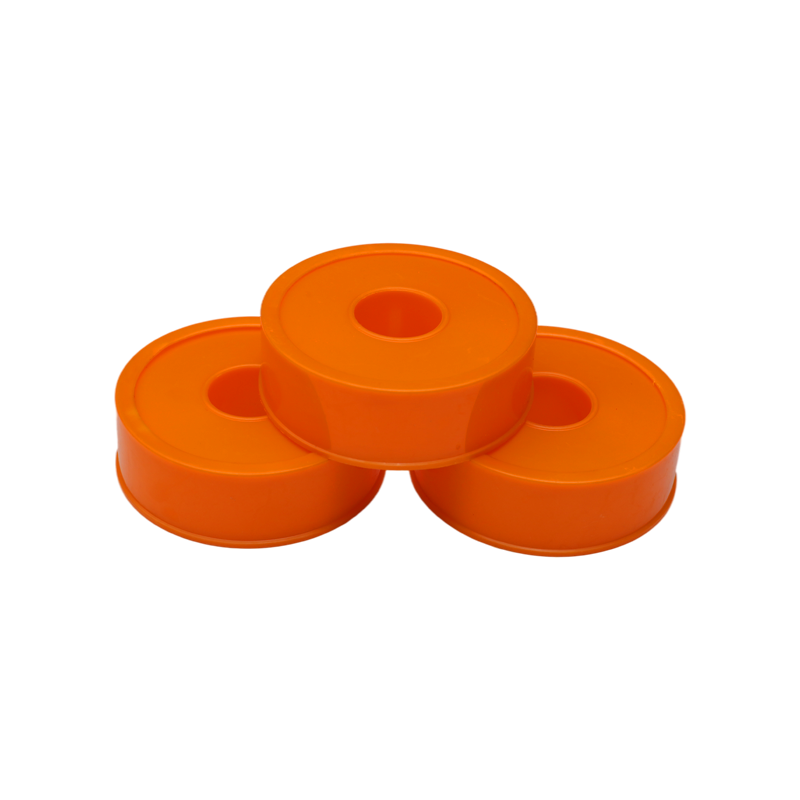

19MM ptfe thread tape ptfe tape can be used for pipeline sealing of strong acid and strong alkali media. This is because PTFE (polytetrafluoroethylene) material itself has excellent chemical corrosion resistance.

The following are some detailed descriptions on the use of PTFE tape in strong acid and strong alkali environments:

1. Chemical resistance of PTFE materials

PTFE is a highly inert material that hardly reacts with any chemical substances. It can resist corrosion from the following media:

Strong acids: such as sulfuric acid, hydrochloric acid, nitric acid, hydrofluoric acid, etc.

Strong alkalis: such as sodium hydroxide, potassium hydroxide, etc.

Organic solvents: such as acetone, ethanol, toluene, etc.

Other corrosive media: such as chlorine, bromine, etc.

Therefore, PTFE tape is very suitable for use in pipeline systems that transport strong acids, strong alkalis or other corrosive liquids or gases.

2. Advantages of using PTFE tape

In the sealing of pipelines with strong acid and alkali media, PTFE tape has the following advantages:

Excellent corrosion resistance: PTFE will not be corroded or degraded even in extreme chemical environments.

Good sealing performance: PTFE tape is soft and has a certain degree of ductility, which can fill the tiny gaps of threaded joints to form a reliable seal.

Temperature resistance: PTFE tape can be used in the temperature range of -200°C to +260°C, and is suitable for chemical pipelines in high and low temperature environments.

No pollution: PTFE material does not react with the medium, so it will not contaminate the transported liquid or gas.

3. Precautions

Although PTFE tape is very suitable for sealing strong acid and alkali media, the following points should still be noted in actual use:

Correct winding method:

When winding, make sure that the tape covers the entire thread surface and is wound in the direction of the thread (usually clockwise).

The number of winding layers is usually 2-3 layers, and the specific number of layers depends on the roughness of the thread and the sealing requirements.

Avoid excessive stretching: During the winding process, do not overstretch the PTFE tape to avoid affecting its sealing performance.

Use appropriate torque: When installing the threaded joint, tighten it with appropriate torque to ensure the sealing effect. Overtightening may cause damage to the tape, and over-loosening may cause leakage.

Check the sealing effect: After the installation is completed, it is recommended to perform a pressure test or leak detection to ensure that the sealing performance meets the requirements.

4. Applicable scenarios

PTFE tape is often used in the following scenarios involving strong acid and strong alkali media:

Acid and alkali delivery pipelines in chemical plants.

Chemical pipeline connections in laboratories.

High-purity chemical delivery in the pharmaceutical industry.

Acid and alkali solution pipelines in water treatment equipment.

5. Alternative options

If the pressure of the pipeline system is higher or the sealing requirements are higher, the following alternatives can be considered:

Liquid PTFE sealant: Suitable for high-pressure environments, with better sealing performance.

PTFE gasket: Used for flange connections, suitable for high pressure and high temperature conditions.

Modified PTFE materials: Some special modified PTFE products may have higher mechanical strength and sealing performance.

19MM wide PTFE thread sealing tape can be used for pipeline sealing in strong acid and alkali media. Its excellent chemical corrosion resistance and sealing performance make it an ideal choice for such application scenarios. As long as it is used correctly and relevant precautions are followed, PTFE tape can provide long-term and reliable sealing effects.

English

English Espa?ol

Espa?ol